Электрондық пошта пішімі қатесі

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Жаңалықтар

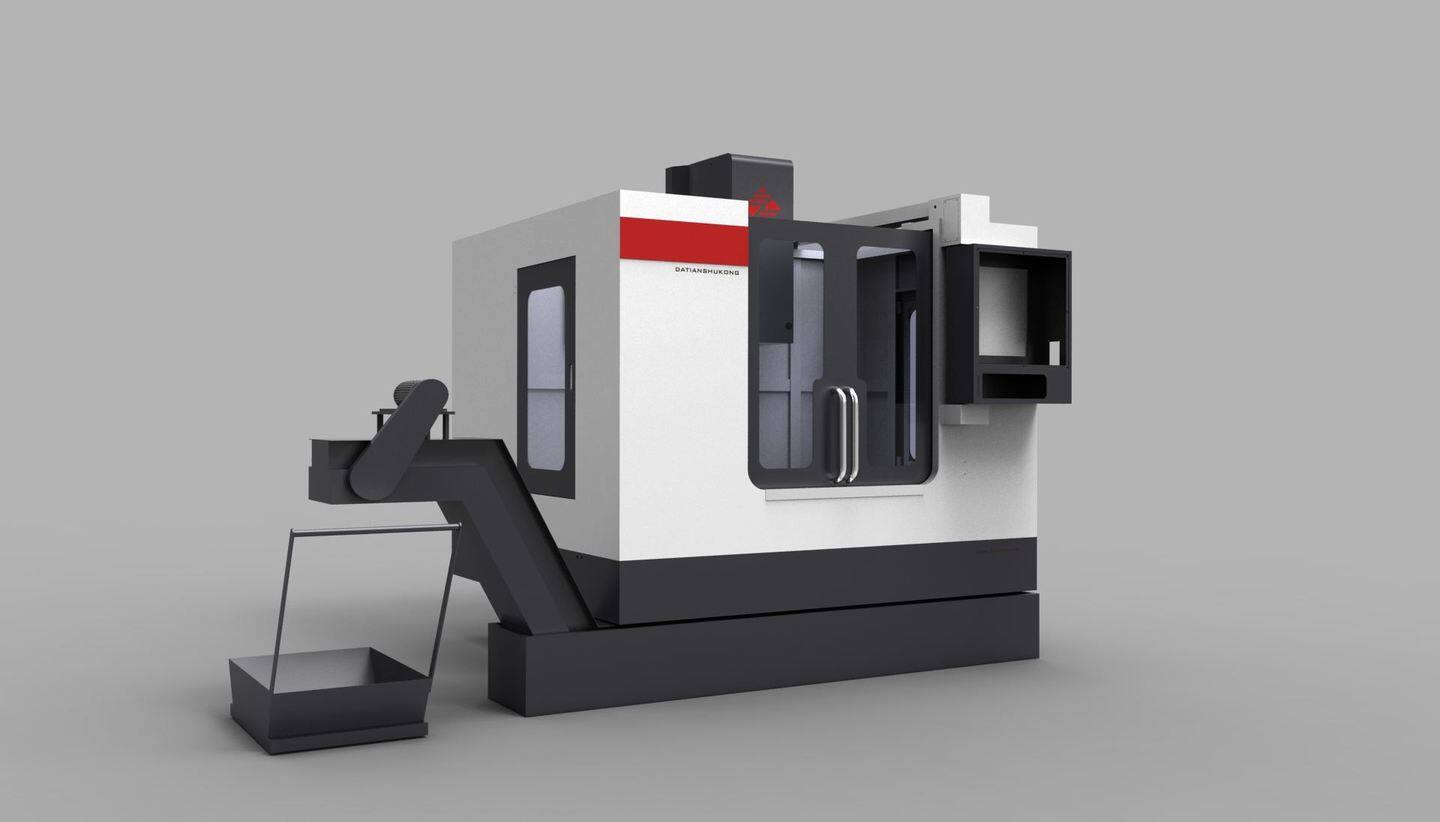

What are the Reasons for Machining Errors in CNC Machining Centers?

The CNC machining center is a kind of high-precision and efficient automatic metal processing equipment, equipped with a multi-station turret or power turret, which can process linear cylinders, oblique cylinders, arcs, and various threads, grooves, worms, and other complex workpieces.

Linear interpolation, circular interpolation, and other compensation functions, it has played a good economic effect in the mass production of complex parts. However, any problem in the control system, drive system, and the electrical and mechanical system of the controlled object will lead to error problems. In the following guide, we briefly introduce the causes and solutions of errors in NC machining.

What are the reasons for errors in CNC machining centers and how to solve them?

- In high-speed machining, the CNC system may have acceleration and deceleration errors and servo system lag errors.

- Due to the inertia of the control system, drive system, and electromechanical system of the controlled object, dynamic errors such as impact, vibration, overtravel, and out of step will occur when the acceleration is large.

- In three-axis NC end milling, the machining error is composed of two factors: linear approximation error and normal vector rotation error.

- The machining error is related to the normal curvature of the machined surface, the tool radius, and the interpolation length, and is proportional to the square of the interpolation length.

- Programming, tool selection, and human factors may also lead to abnormal machining accuracy.

- The rotation error of the normal vector is caused by the rotation of the normal vector of the machining surface along the interpolation line, which is proportional to the size of the tool radius.

- Accuracy error caused by the influence of tool material and cutting oil performance.

Solutions to errors in CNC machining center

- The automatic speed up and down of the CNC system is automatically realized by the software function of the CNC system. The basic requirement is that the selected acceleration and deceleration law should ensure the trajectory accuracy and position accuracy, and ensure the speed, stability, and stability of the acceleration and deceleration process. At the same time, the control algorithm should be as simple as possible and easy to implement by computer.

- For convex surfaces, the normal vector rotation error can be compensated by modifying the tool center position, while for concave surfaces, there is no need to compensate; When the system has no automatic compensation function, the method of reducing the tool radius is used to reduce the error.

- The linear approximation error is determined by the interpolation chord length and is related to the interpolation cycle of the CNC system and the tool feed speed. The linear approximation error can be controlled by selecting a numerical control system with a small interpolation cycle or reducing the feed speed.

- The residual height error of the cutting line is the main factor affecting the surface roughness of the workpiece in surface machining. The error can be controlled by selecting reasonable cutting line width parameters.

- The tool material and cutting oil of the CNC center directly affect the wear degree of the tool, and the tool with fast wear will produce large errors in the workpiece. Selecting the corresponding cutting tools and cutting oils for different processes will help to improve the accuracy of the workpiece.

The above is the reason for the error of the CNC machining center. Only by analyzing the mechanism of error, can we take targeted measures to effectively improve the quality of the workpiece.

Searching for a subcontract cnc machining, cnc machining rapid prototyping, cnc machining steel supplier, wholesaler, manufacturer from China, you can get high-quality products at a nice price.